In this project, I worked as part of a team to design and build a custom brushless DC (BLDC) motor as part of an electromechanics design course. We were given full freedom to design any motor with as much complexity as we would like. Our team decided to go full hands-on with mechanical design, electrical controller, and control.

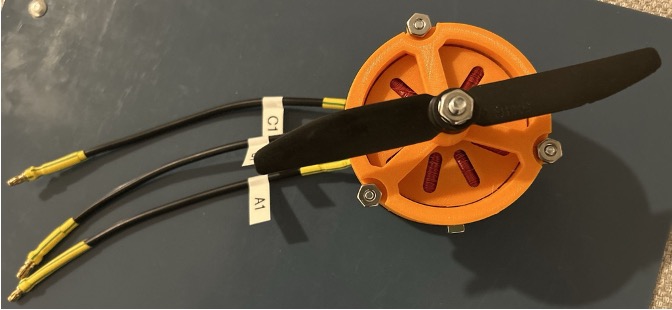

Our final result was a functioning outrunner-style BLDC motor, designed from scratch and tested using a custom motor controller.

Motor Design Overview

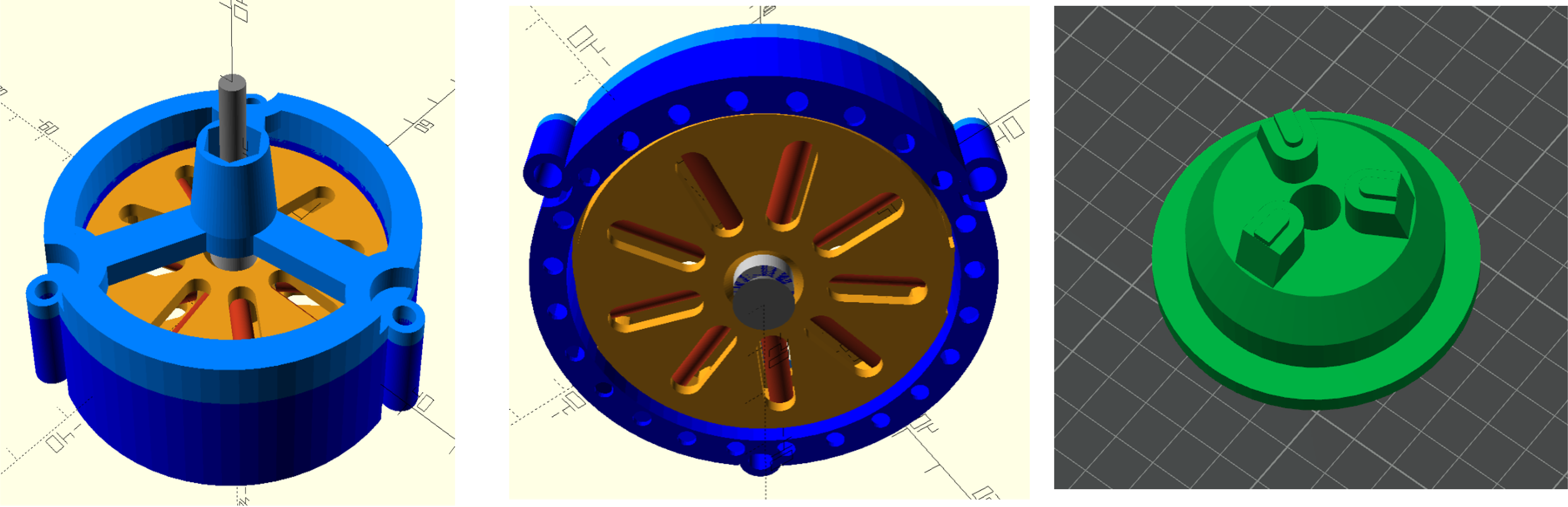

We designed an outrunner BLDC motor with the following key characteristics:

- 9 stator coils arranged in a 3-phase wye configuration

- 24 permanent magnet rotor poles (alternating north/south)

- 3D printed rotor, stator, and base

- Mild steel core segments embedded in the stator

- Neodymium magnets embedded within the rotor print

- Ball bearings and a central shaft for mechanical support

The high pole count helped produce smoother torque and better low-speed behavior.

Mechanical Design and Assembly

The motor housing, rotor, stator shell, and base were designed in CAD and then 3D printed. The stator coils were wound by hand and carefully placed around the iron cores to form the three motor phases.

One of the more challenging aspects was closing the stator assembly without introducing air gaps, as even small misalignments affected performance. The base was designed to securely hold the motor during operation while allowing clean wire routing and gave the motor a lot of stability during operation.

Motor Control and Operation

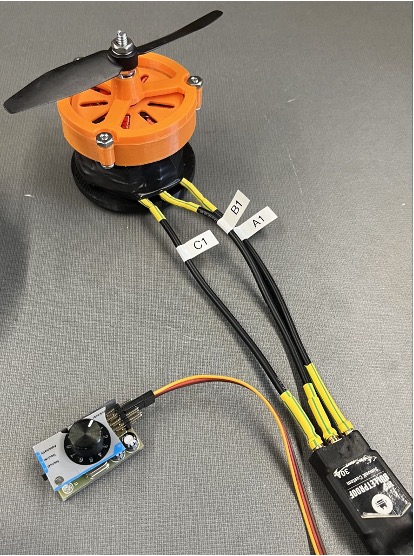

To drive the motor, our team used a custom brushless motor controller designed around an STM32 microcontroller. The controller implemented sensorless control, detecting rotor position indirectly through motor behavior and energizing the stator phases in sequence.

Unfortunately, the controller didn't arrive in time from the fabrication company so all our tests were conducted with an off-the-shelf brushless motor controller.

Once our controller was connected, the motor spun reliably and demonstrated excellent torque for its size.

Results

The motor operated better than all of our expectations. It had almost no vibration, produced reasonably high torque compared to its weight, and had a very polished design.

Seeing a motor that we physically built from individual components operate correctly and at such immense speed that it started producing thrust when we attached a propeller to it was a major milestone of the project.

All of this was despite the challenges we faced of mechanical tolerance during assembly, managing wiring and strain while rotating, and aligning the magnets to remove vibration.

Conclusion

While the project was relatively simple in scope, the real work was in the details. It really provided valuable exposure to real-world motor construction, electromagnetic principles, and the interaction between mechanical and electrical design.

This project strengthened my understanding of how electric motors actually work beyond theory and gave me practical experience with assembly, testing, and debugging physical electromechanical systems.